The injection molding industry plays a vital role in manufacturing, enabling the production of various plastic products on a large scale.

In this article, we will explore how mass production revolutionizes injection molding, enabling customization in bulk. Focusing on China’s plastic molding industry, we will delve into the key aspects that contribute to the success and growth of this sector.

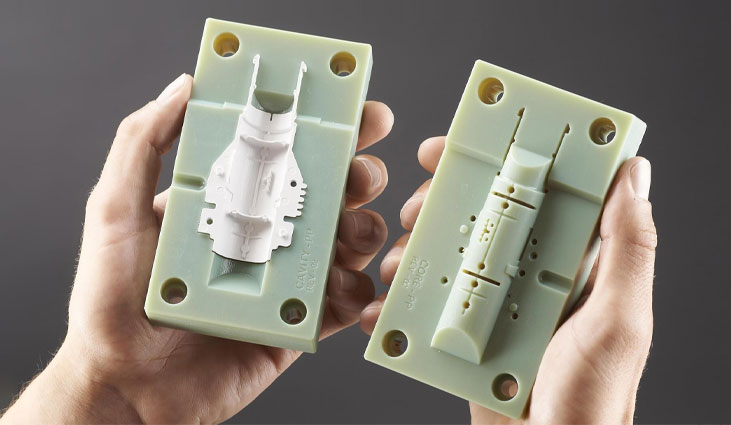

Advanced Technologies and Machinery

To meet the demands of mass production, injection molding industries employ cutting-edge technologies and machinery. Injection molding machines equipped with automation features, precision controls, and modular capabilities make it possible to manufacture complex plastic parts quickly and accurately. By embracing technology, these industries can effectively produce large quantities of custom-designed plastic components within tight timelines.

China’s Plastic Injection Molding Industry

China has become a significant player in the global plastic molding industry. With its vast manufacturing infrastructure, skilled labor force, and competitive pricing, Chinese companies have become leaders in providing molding solutions. Companies specializing in China plastic injection molding can handle massive production volumes while ensuring high-quality products that meet international standards.

Plastic Injection Molding Industry Compared to Pricing and Quality?

China’s plastic injection molding industry is a significant player in the global market, but its performance in terms of pricing and quality can vary. Here’s how it generally compares to other countries:

Pricing:

- Cost-Effective: China is often known for its cost-effective manufacturing. Due to lower labor and production costs, many companies worldwide turn to China for plastic injection molding to save on expenses.

- Competitive Pricing: Chinese manufacturers offer competitive pricing, making them attractive to businesses looking for economical production options.

- Variability: While China is generally cost-effective, prices can vary significantly depending on factors like the complexity of the molds, the materials used, and the production volume.

Quality:

- Varied Quality: China’s plastic injection molding industry has a broad spectrum of quality. Some manufacturers maintain high standards and produce top-quality products, while others may prioritize lower costs over quality.

- Quality Control: Quality control processes can vary among Chinese manufacturers. Companies that invest in rigorous quality control systems can produce products on par with global standards.

- Improving Reputation: Over the years, China’s manufacturing reputation has evolved. Many Chinese manufacturers have improved quality and aligned with international standards.

- Certifications: Some Chinese companies obtain certifications like ISO to demonstrate their commitment to quality, offering assurance to customers.

Quality Control Measures in the Molding Industry?

Inspection and Testing

- Visual inspection: Technicians inspect the molded parts for surface imperfections, color variations, or physical deformities.

- Dimensional measurement: Precise measurements are taken using calibrated tools to ensure the parts meet specified dimensions.

- Functional testing: Some parts require functional testing to confirm that they perform their intended functions correctly.

Material Inspection

Raw material quality control: Thorough inspection and testing of raw materials, including resins and additives, to ensure they meet quality standards.

Process Monitoring

Process parameters: Monitoring and controlling parameters like temperature, pressure, injection speed, and cooling time to maintain consistency and avoid defects.

Mold Inspection and Maintenance

Regularly inspect and maintain molds to prevent issues like wear, corrosion, or misalignment that could affect product quality.

Statistical Process Control (SPC)

SPC involves collecting and analyzing data during production to detect trends, variations, and potential defects early, allowing corrective actions to be taken promptly.

Automation and Robotics

Automated systems and robots are used for parts removal, inspection, and packaging, reducing the risk of human error.

Root Cause Analysis

When defects are identified, root cause analysis is conducted to determine the underlying causes, allowing corrective actions to be implemented to prevent future occurrences.

Training and Certification

It ensures that personnel are adequately trained and certified in injection molding techniques and quality control procedures.

Cost-Effective Mass Customization

Mass production in injection molding brings forth the concept of mass customization – the ability to produce customized products in large quantities without compromising cost-efficiency. Through careful mold designing and tooling, plastic parts can be customized while benefiting from mass production’s advantages. This allows businesses to cater to diverse customer preferences and market demands while maintaining competitive pricing.

Streamlined Design and Prototyping Processes

Efficient design and prototyping processes are integral to successful mass production in injection molding. With computer-aided design (CAD) software and the ability to create rapid prototypes, manufacturers can iterate and refine product designs quickly before finalizing the mold. This iterative process ensures that the final product meets the desired specifications while minimizing errors and reducing the time-to-market.

Quality Assurance and Compliance

Reliable production quality and adherence to industry standards are paramount in molding industries. Manufacturers invest in quality control measures such as rigorous inspections, statistical process control, and material traceability to maintain consistency and reliability. Compliance with international regulations and certifications reassures customers that the produced parts meet the required safety and quality standards.

Conclusion

Injection molding industries, especially in China, have revolutionized mass production and customization of plastic components. By leveraging advanced technologies, cost-effective approaches to mass customization, streamlined design processes, and stringent quality assurance, these industries have transformed how plastic products are produced in large volumes. As the demand for plastic components grows, molding remains a pivotal part of modern manufacturing, enabling customization in bulk without compromising efficiency or quality.