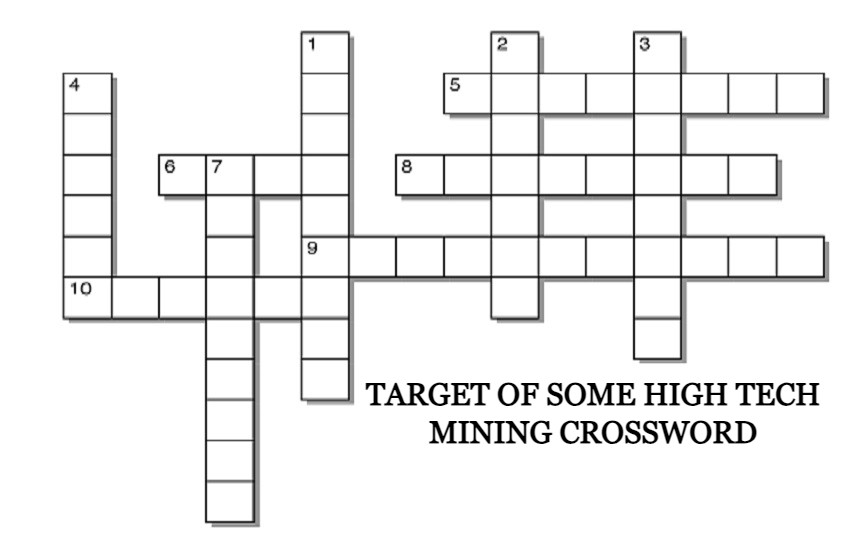

Introduction: Target of Some High Tech Mining Crossword

Target of Some High Tech Mining Crossword: The extraction of natural resources like minerals, metals, and fossil fuels is essential for supporting key industries and providing materials needed for manufactured goods, energy production, and infrastructure development across the globe. The mining sector has experienced tremendous change over the past few decades with the introduction of advanced technologies that have transformed traditional techniques for locating, accessing, and processing mined materials.

The integration of high-tech tools and solutions in mining operations has enabled enhanced productivity, efficiency, safety, and sustainability. From deploying sophisticated sensors for identifying targets to using AI and automation in extraction processes, technology is propelling the mining industry into a new era. While new opportunities have emerged, mining companies also face fresh challenges in leveraging complex innovations, addressing regulatory concerns, and balancing environmental impacts.

As mining progresses to utilize ever more sophisticated technologies, understanding the transformative evolution of resource extraction practices will be key for driving future growth. This article will delve into the secrets behind high-tech mining, exploring cutting-edge techniques and strategies while uncovering opportunities, obstacles, and the industry’s technological trajectory.

Understanding High-Tech Mining

High-tech mining incorporates advanced tools and techniques throughout the resource extraction process, from initial prospecting to final processing and analysis. Also referred to as precision mining, the approach allows targeted, optimized operations.

Defining High-Tech Mining: Target of Some High Tech Mining Crossword

At its core, high-tech mining leverages sophisticated technology to locate potential deposits, carefully target extraction, and refine materials with enhanced accuracy and efficiency compared to conventional methods. Key characteristics include:

- Automation, robotics, AI, and sophisticated software usage

- Data-driven exploration, analysis, and decision making

- Advanced sensory, monitoring, and control systems

- Innovative equipment such as drones and driverless haul trucks

- Real-time operational optimization and adjustment

- Integrated communications networks and information management

Technological Innovations in the Mining Industry

A range of advanced innovations have emerged across the mining sector:

- Autonomous equipment like automated drill rigs and intelligent machine systems

- Aerial drones and advanced 3D survey mapping

- Predictive analytics, machine learning, and expert systems

- Robotic exploratory robots and automated assistants

- Remote operations centers and virtual reality simulation training

- Internet of Things (IoT) sensors and smart helmet technologies

- Supply chain integration and blockchain logistics platforms

Impact of Technology on Resource Extraction

The influence of high-tech solutions is significant:

- Improved safety via reduced on-site personnel and remote operation

- Enhanced productivity through automation and AI optimization

- Better resource targeting and extraction from comprehensive data insights

- Reduced costs with lower equipment downtime and shared data access

- More sustainable practices from precision extraction and conservation

In essence, high-tech mining enables smarter, leaner, and more responsive processes for firms aiming to improve output, reduce unnecessary waste, and streamline complex operations.

The Secrets Behind Targets

Identifying which deposits are most promising has always been a central concern in mining. Advanced technologies now enable much more sophisticated targeting strategies and scientific reserve estimations.

Identifying High-Value Mining Targets

Various tools allow superior mapping and modeling:

- High-resolution 3D seismic surveying and sub-surface imaging

- Detailed aerial geophysical surveys from drones

- Vast data from gravimetric, geomagnetic, radiometric analysis

- Sophisticated ore deposit modeling software

- Machine learning for pattern recognition

- High performance computing for complex simulations

This provides extensive data to highlight drilling targets with high concentration or quality deposits based on detailed mineral composition analysis.

Precision Targeting Strategies

By combining digital modeling, AI, and simulations, firms can:

- Focus exploration on locations with maximum yield potential

- Plan optimal extraction approach and required capacity

- Design equipment configurations and mine layouts

- Determine economic viability and costs

- Continuously adjust plans based on real-time data

Detailed predictive analytics allow strategically designed, dynamic operations.

Unveiling the Science of Target Selection

Advanced analytics converts raw data into actionable insights for locating ideal sites rich in desired resources. Key techniques include:

- Laser and X-ray mineralogical analytics for composition analysis

- Predictive data modeling and machine learning algorithms

- Powerful geoscience data platforms

- Real-time data integration from numerous monitoring systems

- Data visualization dashboards for clear decision making

By leveraging these tools, mining experts can precisely focus efforts based on scientific reserve estimations and predicted value.

Cutting-Edge Extraction Techniques

Once targets are identified, smart mines utilize a range of sophisticated technologies for accessing and extracting resource deposits:

Advanced Mining Equipment and Machinery

- Automated drill rigs for targeted, unmanned operation

- Driverless trucks, diggers, and transport vehicles

- Intelligent robotic excavation machinery

- Remote drone equipment for surveying pits

- Conveyor belts and pipelines with integrated sensors

Robotics in High-Tech Mining

- Automated roving explorer robots in tunnels

- Snake-arm robots to access narrow veins

- Self-driving ore trucks for material transport

- Machine learning optimization of robot movements

- Computer vision ore analysis and selection

- Collaborative robotics for assisting human miners

Environmental Considerations in Modern Mining

- Low-impact, selective extraction methods

- Autonomous electric vehicles to reduce emissions

- Real-time environmental monitoring

- Tailings management automation

- AI-driven predictive maintenance and safety

- Effective dust suppression and water conservation

Advanced equipment allows mining companies to improve productivity and reduce risks while minimizing environmental damage through precision extraction.

Strategies for Technological Resource Unveiling

Digital capabilities allow comprehensive tracking and analysis to optimize the entire mining value chain. Key solutions include:

Data Analytics in Mining

- Integration of operational and business data

- Monitoring asset health, performance, costs

- Identification of process bottlenecks

- Optimization of schedules, equipment, flows

- Forecasting production quantities and maintenance

AI and Machine Learning Applications

- Predictive maintenance to prevent outages

- Natural language processing for parsing unstructured data

- Anomaly detection in equipment sensor data

- Optimization of complex interconnected processes

- Chatbots and virtual assistants for advice

Remote Sensing and Geospatial Technologies

- Real-time visualization of operations

- Tracking of team members, assets, and equipment

- Remote management of sites and collaborative decision making

- 3D visualization and digital twin modeling

Advanced analytics unlocks insights from vast data while enabling informed, responsive management of high-tech mining activities.

Challenges and Solutions

While modern mining techniques create new opportunities, they also pose important challenges surrounding sustainability, cyber risks, and regulations.

Environmental Concerns and Sustainable Practices

High-tech mining enables more responsible practices but still impacts the environment. Solutions adopted by leaders include:

- Renewable energy for electrified, lower-emission equipment

- Responsible water management and conservation

- Tailings and waste management automation

- Biodiversity protection and ecosystem conservation

- Rehabilitation using drones and remote sensing

- Stricter internal governance and compliance processes

Cybersecurity in High-Tech Mining

With increased connectivity and data exchange, security risks grow. Methods to enhance protection include:

- Secure network architecture and access controls

- Employee cybersecurity training

- Comprehensive data encryption

- Third-party cybersecurity auditing

- Incident response plans and system redundancy

Regulatory Landscape and Compliance

Navigating various regulations surrounding safety, operations, and environmental protection is challenging. Leading firms:

- Maintain legal departments tracking policies

- Develop strong relationships with regulators

- Participate in shaping new regulations

- Adopt standardized reporting procedures

- Regularly conduct audits and risk assessments

Proactive efforts to address these issues is allowing the industry to find a sustainable balance despite hurdles.

Case Studies: Success Stories in High-Tech Mining

Rio Tinto – The mining giant has embraced automation across operations, including the world’s first fully autonomous heavy-haul, long-distance rail network. Rio also relies on data analytics and integration for real-time monitoring and optimization.

Goldcorp – The gold mining firm uses smart sensors to track underground miner locations, monitor oxygen levels and potential gas leaks, and optimize ventilation efficiency at its Éléonore mine.

BHP Billiton – The company utilizes predictive analytics, remote equipment operation, and integrated data platforms to enhance safety and productivity at sites like the massive Escondida copper mine in Chile.

AngloAmerican – The multinational mining company has been an early adopter of new techniques at its platinum, diamond, and copper mines, including robots, virtual reality, and big data analytics.

These examples demonstrate both the extensive applications and tangible benefits of emerging technologies across different mining organizations and commodities.

The Future of High-Tech Mining

Continued innovation and adoption of new solutions will shape the mining industry for years to come. Exciting developments on the horizon include:

Target of Some High Tech Mining Crossword

- Increasingly autonomous operations and equipment

- Expanded use of robotics and drones

- Next-gen data analytics and artificial intelligence

- Advanced wireless mesh networks and sensors

Anticipated Innovations and Developments

Several key innovations expected to expand in mining include:

- Extraction drones equipped with lidar, sensors, cameras, and grapples to access hazardous areas

- Expanded augmented and virtual reality applications for equipment operation, maintenance, and training

- Further automation of water management, tailings disposal, and environmental compliance

- Transition to electric or hydrogen-powered autonomous haul trucks, reducing diesel dependency

- Safer working conditions with remotely operated and automated equipment reducing direct human exposure to hazardous environments

- EnhancedMine integrations linking every part of the mine’s ecosystem into a converged digital landscape, optimizing the entire value chain

These forthcoming innovations will allow mining companies to improve health and safety, achieve greater productivity, reduce costs, and strengthen sustainability.

Conclusion

The mining industry is in the midst of a major technological transformation, embracing automation, data-driven platforms, advanced analytics, and innovative techniques to unlock operational insights. As high-tech mining continues maturing, companies must focus on integration, collaboration, and environmental stewardship.

With responsible implementation, high-tech resource extraction can support safer working conditions, optimized productivity, reduced waste, and access to essential materials for global progress. By revealing mining’s technological secrets and new best practices, the industry can sustainably meet growing mineral resource needs. The future looks bright for firms able to effectively leverage data-driven, highly automated mining powered by cutting-edge innovations.

FAQ: Target of Some High Tech Mining Crossword

Q: How has technology revolutionized the traditional mining industry?

A: Technology has revolutionized mining in numerous ways, from sophisticated robotic equipment replacing manual labor to advanced data analytics optimizing entire operations. GPS, autonomy, sensors, machine learning, drones, and control systems have transformed resource discovery, extraction, transport, and processing. These innovations enable improved safety, efficiency, accuracy, and sustainability in the mining industry.

Q: What are the key challenges faced by high-tech mining operations?

A: Key challenges include managing large upfront technology investments and retraining personnel, securing data and networks from cyber threats, navigating complex regulations, and addressing environmental sustainability concerns related to land use, waste, water management, and ecosystem impacts. Adopting new innovations can also face resistance from traditional company cultures.

Q: Can high-tech mining contribute to environmental sustainability?

A: Yes, high-tech mining can support more sustainable practices through precision extraction methods, automated electric vehicles lowering emissions, centralized monitoring to minimize contamination, and data-driven analytics to reduce waste. However, mining remains resource intensive. Continued efforts around renewable energy, reduced water use, rehabilitation practices, and environmental regulation are still required.

Q: How do data analytics and AI play a role in modern mining practices?

A: Data analytics and AI are crucial for optimizing nearly all aspects of high-tech mining operations. Analytics provides real-time insights into equipment performance, identifying problems instantly. AI optimizes complex interconnected processes, schedules preventative maintenance, and enhances forecasting. Together these technologies improve productivity, lower costs, and strengthen sustainability.

Q: What are the potential risks associated with the use of robotics in mining?

A: Risks include programming errors leading to accidents, network vulnerabilities leaving robotics open to hacking, lack of flexibility to identify and respond to unforeseen circumstances, significant upfront costs, and displacing human workers. Careful implementation focused on collaborating with and augmenting people can help minimize these risks.